Making the Earth

More Stable

Our Services

Soil Stabilization

Designed for value engineering.

Soil Stabilization is the cost-effective, long-term physical and chemical alteration of soils to enhance their physical properties. It can improve R-values, sheer and unconfined compressive strengths, and permanently lower the soil’s permeability to water. Stabilization can be used to treat a wide range of less than desirable soils, from expansive clays to granular materials. This is all done on your jobsite and in-place.

Not only does Soil Stabilization reduce your up-front cost by up to 50%

– it costs much less than an aggregate base/select fill section, – it provides future savings because it increases the life of the section and reduces maintenance costs.

Benefits of Soil Stabilization:

Prepare for winter conditions and keep the job going.

You can winterize your site well before winter sets in. This preventative measure eliminates down-time and lasts throughout the length of the project. In wet conditions, your crews can get back on-site immediately after the rains have stopped.

Winterization/dry-up

Keeps the job on schedule throughout the winter.

Western Stabilization’s Winterization /Dry-Up of your site eliminates down-time. It allows you to go back to work and start construction just one day after the completion of the soil treatment. The beauty of our Winterization/Dry-Up is that it protects your site throughout the entire construction project – one treatment is all it takes!

You can even winterize your site well before winter sets in. This process saves you money in the long run.

Adds value engineering.

You can potentially gain some structural value when you winterize your site. Western Stabilization’s Winterization/Dry-Up process reduces expansion and increases the strength of the soil, allowing you to decrease the rock and pavement sections. Winterization/Dry-up gives your engineers options in designing structural sections that can save you money.

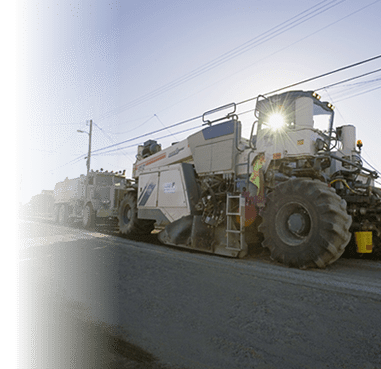

Equipment, manpower & know-how for all weather conditions. Western Stabilization has the equipment, experience and people to dry-up your site when you need it. We are well equipped to respond to your needs immediately. Western provides specialized machinery, specifically designed to handle the muddiest conditions.

Back to work in 1-3 days or in 1-3 months?

You decide.

Asphalt Pulverization Recycling

Recycling the existing asphalt on-site to create a better product.

Asphalt Pulverization Recycling, – also known as “Full Depth Reclamation,” – is becoming a much more common practice. This process allows you to recycle an existing asphalt section, along with a portion of the base material. This newly pulverized recycled material can now be used as a new base on-site or at a different location.

There’s no down-side!

Asphalt Pulverization Recycling saves the cost of excavating the old base, as well as the cost of importing new base materials. The options are simple. Bring in new aggregate at considerable cost or recycle your existing asphalt to create a new base at minimal cost.

Some benefits of Asphalt Pulverization Recycling are:

High-production recycling machines.

Western Stabilization’s recyclers are state-of-the-art, high-production pulverizing machines. This equipment can achieve gradation that typically meets Class 2 ASB specifications.

There are several options for recycling your pulverized asphalt. Please call us to discuss your specific situation.

Foamed Asphalt Recycling

Western introduces Foamed Asphalt Recycling to Western United States.

Western Stabilization was the first contractor to bring Foamed Asphalt Recycling to the Western United States. It was, in fact, our company that introduced Foamed Asphalt Recycling to Caltrans.

Western Stabilization owns Wirtgen WR series recyclers. We utilize the machines best suited for your project.

Projects have ranged from state highways to smaller, private roads, large parking areas, and intermodel yard reconstruction projects.

Viable, cost-effective and environmentally sensitive rehabilitation of roadways.

Foamed Asphalt Recycling is an “in-place” reconstruction process of existing roads and other pavement sections. Recycling is more cost-effective than total reconstruction. Foamed Asphalt Recycling has been known to cut reconstruction costs by fifty percent.

Provides longterm value.

Foamed Asphalt lengthens the life of the finished product and decreases future maintenance considerably. Foamed Asphalt creates a flexible, non-expansive and fatigue-resistant base, with strength characteristics approaching those of cemented materials.

Low impact on the public and surrounding businesses.

Highway 20 was daily re-opened to traffic within 3 hours of completing the finishing operation.